EDS® Building Performance

Identifying Construction Defects and Performance Limitations

Buildings are exposed to the risk of quality and performance shortcomings during construction and throughout their lifecycles. These limitations impact environmental comfort and the energy performance of buildings and the systems serving them.

EDS® uses non-destructive testing to find defects in building construction or limitations in system performance.

A combination of field sensor testing, thermography, and systems performance interrogation is used to establish what exactly is happening within a zone or building. This is then compared to what is 'supposed to' happen in the zone.

Often what appear to be electrical or mechanical defects turn out to be unintended human behaviour or inappropriate control settings that are usually easy to remedy.

EDS® evaluates:

- Damp/Condensation/Mould

- Heat Loss

- Heat Gains

- Solar Radiation

- Infiltration

- Insulation Defects

- HVAC distribution & performance

- Electrical & Mechanical Defects/Imbalances De-lamination

- HVAC and natural Ventilation Controls

- Air Velocity

- Cooling Capacity

- Draught Detection

- Air Quality

- Volatile Organic Compund (VOC) Detection

Building Performance Testing & Monitoring

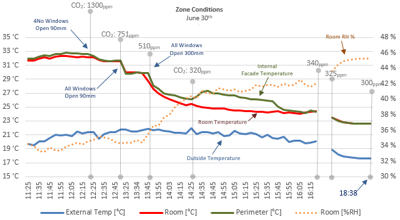

Air Quality [CO2] & Comfort Conditions. Establishing Comfort Levels, Overheating, Under-heating, Thermal Asymmetry, Draughts & Condensation

The built environment is not typically a finished product; changes to fabric, layout, operations, and under-performing building services can negatively alter the original intent of the building.

The sources of draught, for example, can be detected and often traced back to material infringements, remote occupant behaviour or inappropriate BMS or Access system settings. Poor air quality can point to mechanical or control failure; or, inappropriate design.

EDS® examines and monitors workspace, building, and systems performance.

Thermography

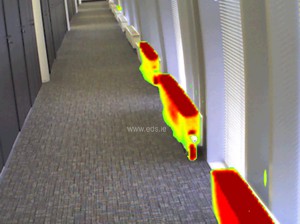

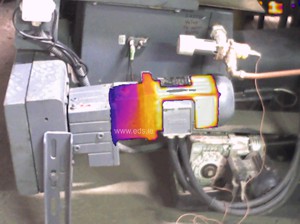

Using Thermal Imaging To Identify Energy Performance and Building Defects

This can help building owners/managers make informed decisions on required repairs, helping to save energy and restore comfort.

EDS® uses thermography to determine the location, integrity, status, and performance of heating, ventilation and cooling systems.

Thermal imaging is used to detect:

- Missing, damaged, or inadequate insulation

- Building envelope air leaks - infiltration

- Draughts

- Dampness, moisture, water ingress or mould

- Sources of energy inefficiencies

- Locations of mechanical / electrical defects or inefficiencies

- Structural Defects

- De-lamination

- Preventative maintenance issues

EDS® uses thermography to locate and inspect heating and cooling distribution systems. Non-destructive testing can be used to quickly detect underfloor heating system performance or defects.

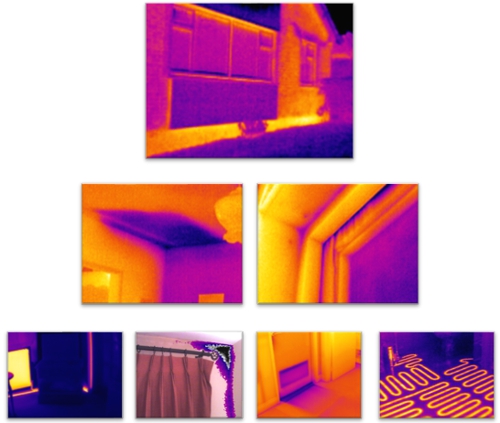

Domestic Thermal Survey

Establishing Domestic Comfort Levels. Detecting Overheating, Under-heating, Thermal Asymmetry, Draughts & Condensation

EDS® also offers domestic thermal surveying services. A thermal survey of the external building envelope is conducted to highlight detected heat loss or ‘fabric anomalies’.

An internal survey will include a thermal inspection of all solid and glazed façade elements, highlighting any apparent defects or observations relating to:

- Insulation Integrity (Determine if insulation is displaced or removed)

- Thermal Bridging (Locate areas low of thermal resistance that may require insulation or repair)

- Sources of Moisture (Locate apparent leaks or other sources of moisture)

- Source of Draughts (Locate draughts and recommend remedy or compromise)

- Potential for Condensation or Mould (Identify areas promoting condensation or mould and advise)

- Internal Radiators (Detect any apparent imbalances in the heating system)

- Underfloor Heating UFH (Ensure integrity and check for apparent leaks)

The conclusion and recommendations of the survey are presented in a detailed thermographic report.

Note:

- The survey is best conducted after all rooms in the dwelling are heated for a few hours.

- It is important that, where possible, all photos or other hanging objects are removed from external walls.

- It is recommended that all furniture be moved at least 1m away from walls.

- Access is required to all rooms of the dwelling, including the attic, basement and boiler room.

- Underfloor heating survey requires that all furniture is removed from the floor.

EDS® Projects |

|

|

Community Care Centre

Building & systems performance analysis. . Passive Design • Design Validation • Performance Analysis • CFD |

|

Smoke/Fire Analysis

Fire & smoke CFD analysis of landmark commercial building in Dublin. Passive Design • Smoke/Fire Simulation • Design Validation • Performance Analysis • CFD |

|

Government Authority HQ

Building & systems performance analysis. Thermal Simulation • Design Validation • Performance Analysis • CFD |